ECS-EBU Anti-icing Ducts

25 years’ experience in research, 1D bending, hydroforming, high-temperature super-plastic moulding, and welding very high-temperature (> 1000° C) critical pipes made from nickel alloys.

MHG AEROSPACE is your perfect partner because it can offer you a highly competitive, comprehensive service ranging from studies to the certification of all ECS-EBU-anti-icing ducting projects requiring know-how and technology. MHG AEROSPACE’S hydroforming technique involves bending curved ducts in a cold hydraulic process to create complex shapes, and vibration dampers which can be inserted into the confined environments of engines, nacelles, or aircraft, whilst respecting the pressure drop and mass reduction values set by customers.

MHG AEROSPACE employs more than 200 people and is part of the Friedrich BOYSEN INTERNATIONAL GROUP, which generates 7 billion euros per year. It is based in the Stuttgart area of Germany.

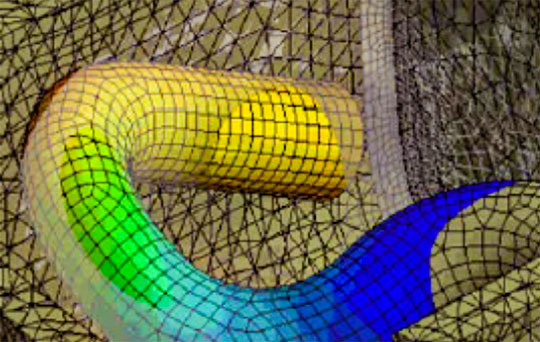

MHG AEROSPACE has a research team consisting of 20 permanent engineers. The tools required for its manufacturing are made in-house, in compliance with aeronautical standards, and using 3D software tools. TUBE EXPERT, a simulation tool, allows ultra-fast modelling, which means significant economies of scale at the study stage, to guarantee you a highly responsive and very competitive service. Its expertise is based on extensive experience acquired over more than 15 years in research and the development and manufacture of TBV ducts & HPT-ACC ducts. Its exceptional reliability is evidenced by 18 world championship titles.

MHG AEROSPACE has a research team consisting of 20 permanent engineers. The tools required for its manufacturing are made in-house, in compliance with aeronautical standards, and using 3D software tools. TUBE EXPERT, a simulation tool, allows ultra-fast modelling, which means significant economies of scale at the study stage, to guarantee you a highly responsive and very competitive service. Its expertise is based on extensive experience acquired over more than 15 years in research and the development and manufacture of TBV ducts & HPT-ACC ducts. Its exceptional reliability is evidenced by 18 world championship titles.

MHG AEROSPACE is set up to produce first demonstration models at very competitive prices and lead times, as it possesses all the internal resources required for manufacturing tubes with a diameter range of 16 – 400 mm, in compliance with AMS standards, for materials such as titanium, Inconel®, aluminium and special nickel-based alloys.

- Wall thickness 0.5 to 3 mm.

- Maximum length over 1,000 mm.

By agreement with its customers, MHG AEROSPACE also obtains supplies from the major certified tube manufacturers.

Products

Certifications and qualifications

MHG AEROSPACE is ISO 9001 certified and applies the aeronautical standards set by its customers.

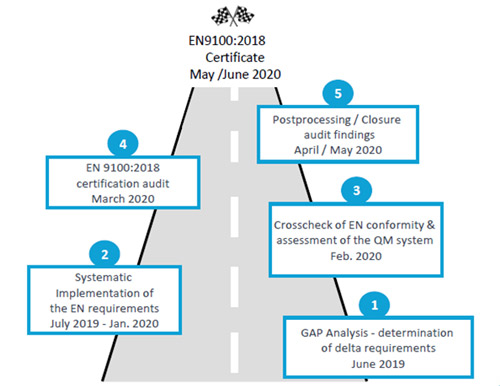

MHG AEROSPACE is currently working with the AERO IMPULSE consultancy to obtain EN 9100 certification by mid-2020, and then NADCAP and ISO 14001 certification.

MHG AEROSPACE produces FAIR files according to the requirements of its clients for aeronautics